The core scenarios of water use in slaughterhouse production include livestock and poultry cleaning, equipment and knife cleaning, viscera processing, as well as floor and workshop flushing. Each of these scenarios places different emphases on water quality due to varying points of contact and functions, but all must meet basic requirements for hygiene and production compatibility (as per the “Sanitary Standard for Drinking Water” (GB5749-2022)).

Production water is critical to slaughterhouse operations, with its core value reflected in five aspects:

1.Ensuring food safety – clean water for washing animals, carcasses, and equipment interrupts microbial contamination and reduces the risk of foodborne illnesses;

2.Maintaining production efficiency – as a key medium across production stages, it ensures smooth operations like dehairing and washing, preventing equipment shutdowns and process stagnation;

3.Improving meat quality – clean water and proper temperature reduce meat deterioration, preserve good appearance, and extend freshness;

4.Meeting compliance – water must meet drinking water standards to avoid regulatory penalties;

5.Enhancing operational environment – reduces workshop contamination and safety hazards, protecting worker health.

Stable and high-quality production water is the foundation of normal operation and sustainable development in slaughterhouses. Therefore, treatment of production water is essential. RO permeate water, with its excellent purification capacity, has become an indispensable part of this process.

I. Case Information

II. Equipment Selection

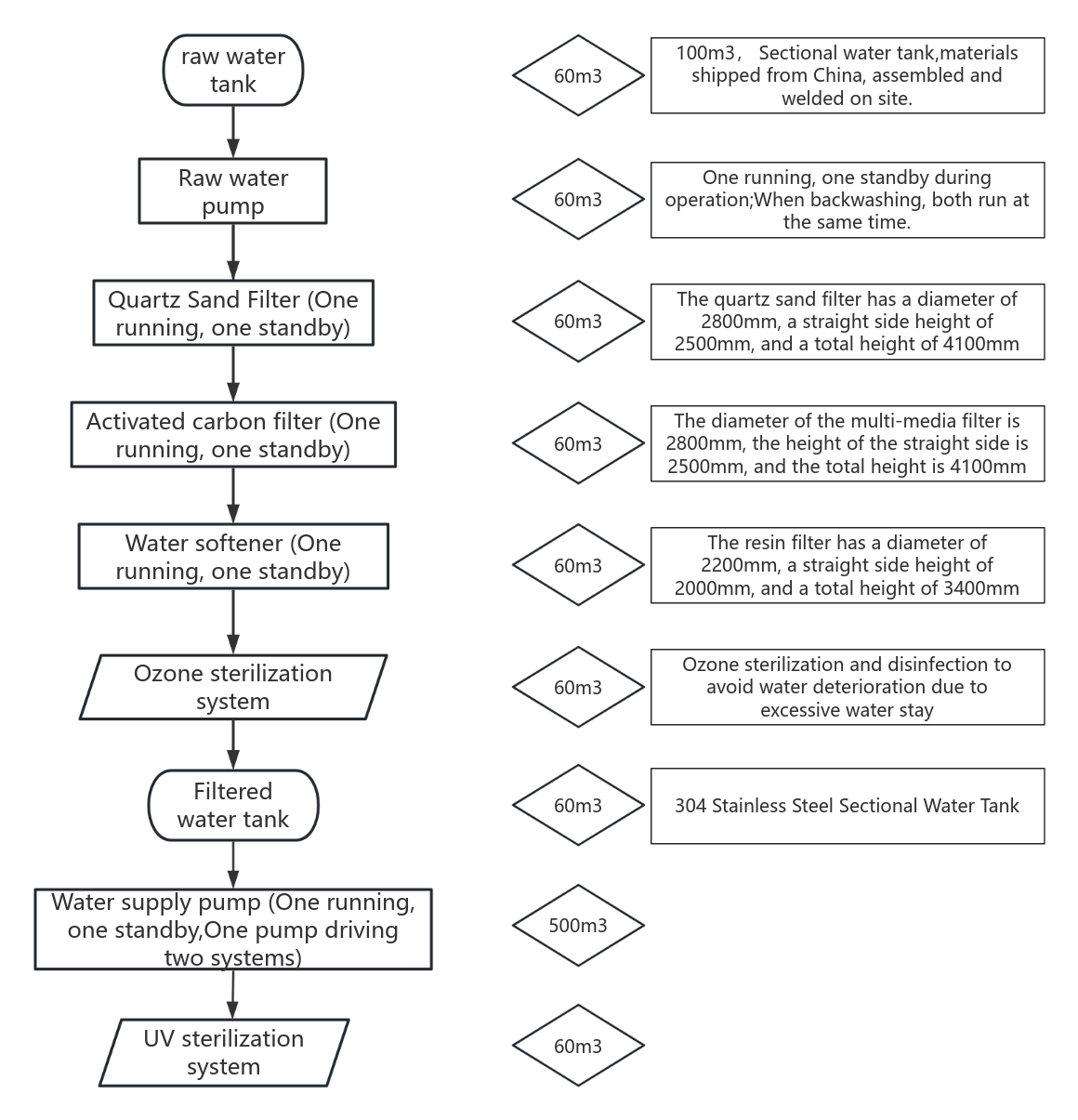

(I) Raw Water Tank

A 100m³ assembled tank is selected. The tank offers large storage capacity, accommodating the periodic water demand fluctuations in slaughterhouses (such as water usage spikes during peak processing hours). The raw water tank allows advance storage to avoid production interruptions due to unstable raw water supply. SUS304 stainless steel material prevents rust contamination of raw water, ensuring a solid foundation for downstream water quality and meeting hygiene requirements for meat processing (GB5749-2016 “Sanitary Standard for Drinking Water”). Due to the space limitation of a 40-foot container and inconvenience of transporting a welded tank, on-site welding and assembly is chosen. With clear instructions and labeling, the assembly is simple.

Figure 1: Stainless Steel Water Collection Tank

Equipped with a level gauge with analog signal transmission, facilitating automatic system control of water inflow and outflow. It prevents overflow or water shortage and allows real-time monitoring to maintain a stable tank water level. The drain outlet and valve are specified as DN100, PN1.0, with a DN100 stainless steel flange reserved as per customer requirements. This design facilitates cleaning and draining of the tank. The EPDM lining and 304 valve plate provide excellent corrosion resistance and sealing, ensuring a reliable draining process. The system connection pipelines are made of UPVC, which is lightweight, easy to transport, and corrosion-resistant.

(II) Raw Water Pump

The raw water pump handles raw water transfer. In this case, two SUS304 pumps (60t/h, 40m head) are used with a one-duty-one-standby configuration. During operation, backwashing is enabled simultaneously. As backwashing requires higher flow rates, activating the standby pump doubles the total flow. This ensures sufficient flow and pressure for effectively washing broiler chickens and pigs (≥0.3MPa required after broiler claw removal/gutting rinse; 0.2–0.5MPa for pig viscera rinsing). It also ensures continuous system water supply and equipment efficiency without needing a separate pump for backwashing, thus reducing procurement costs and installation space.

Figure 2: Raw Water Pump

(III) Filters

1. Quartz Sand Filter

Production water in slaughterhouses must meet GB5749 standards for “turbidity ≤3 NTU, no visible matter” (e.g., clean water is required for pig carcass washing and pre-slaughter spraying to avoid meat contamination). This case uses two 2200*3350 carbon steel tanks that fit into a 40-foot container. Internally lined with anti-corrosion rubber, they are equipped with DN80 electric ball valves and multi-layer quartz sand media. A dual-tank (duty/standby) design meets the 60t/h capacity requirement and ensures continuity, stability, and efficiency of the water supply system. During backwash, one unit continues to operate, maintaining productivity while saving on spare equipment costs for purchase, installation, and maintenance.

Figure 3: Quartz Sand Filter

2. Activated Carbon Filter

With the same tank specs as the sand filters, two carbon steel tanks with DN80 electric ball valves are used, filled with 140 bags of nutshell activated carbon.

Water must be odor-free in slaughterhouses (odors affect meat quality), and organics/chlorine residues may breed bacteria or interfere with downstream disinfection. Activated carbon adsorbs odors and trace pollutants. The “dual operation + single backwash” design ensures continuous adsorption without water quality fluctuations due to downtime. Over time, adsorption sites saturate and require timely backwash or replacement; otherwise, pollutants may leak and cause odors. Under normal dual operation, total treatment capacity reaches 70–80t/h, reducing adsorption pressure on individual units and extending saturation intervals. During backwash/regeneration, one unit is taken offline while the other remains in operation, ensuring continuous deep filtration. This is especially suitable for slaughterhouses’ hygiene requirements of “odor-free, low organics” water.

Figure 4: Activated Carbon Filter

3. Resin Softening Filter

Two 1800*3150 FRP tanks are used, filled with 001*7 ion-exchange resin and paired with 3000L salt tanks.

Steam boilers and scalding tanks are highly sensitive to hard water—excess Ca²⁺ and Mg²⁺ cause scaling, reducing heat efficiency and risking pipe damage. The resin absorbs these ions and requires regeneration (via salt solution). The regeneration process is time-sensitive and condition-specific. Single-tank regeneration may be rushed to restore supply, risking incomplete regeneration and reduced resin capacity. The “offline regeneration” design allows thorough regeneration without interrupting supply, ensuring full resin recovery. Alternating regeneration between two tanks reduces overuse of a single tank, minimizing resin aging and extending lifespan, thus lowering replacement costs. This meets GB5749 requirements for total hardness (≤550mg/L as CaCO₃), prevents scaling in high-temperature systems (e.g., ≥40°C for pig scalding, ≥82°C for disinfection), and reduces post-process contamination.

(IV) Ozone Sterilization System

In this case, ozone sterilization is applied before water enters the storage tank. If UV disinfection were used instead, microbes might regrow in the tank due to long residence times. Ozone dissolves into water and decomposes slowly into oxygen, maintaining a residual disinfectant concentration and forming a “continuous sterilization barrier” that effectively inhibits microbial growth in the tank.

Ozone ultimately decomposes into oxygen (O₂), unlike chlorine disinfection which produces harmful byproducts like trichloromethane. It also does not alter pH or increase salinity, ensuring no interference with resin softener ion exchange efficiency. These traits align with slaughterhouse requirements for “clean water quality,” ensuring disinfection does not introduce new pollutants.

Figure 5: Ozone Generator

(V) Product Water Tank

A 500m³ tank is selected to accommodate the distinct time-based variations in slaughterhouse water usage—peak demand during processing, lower at night. This large-capacity design enables off-peak storage. SUS304 stainless steel modular design is adopted, assembled on-site for easier transport. A fully welded tank would not fit a 40-foot container, whereas the modular setup, with labeled parts, simplifies field assembly.

Equipped with a level gauge and analog signal output for real-time level monitoring, aiding system control of inflow/outflow. DN200, PN1.0 drain outlets and valves are selected, with reserved DN200 stainless steel flanges per customer request for tank cleaning and drainage. Made with cast iron valve body, EPDM lining, and 304 valve plate, these components provide good corrosion resistance and sealing. Piping uses UPVC for light weight, ease of transport, and chemical resistance.

(VI) Water Supply Pump

A constant-pressure water supply system includes two SUS304 pumps (70t/h, 45m head) in a duty/standby configuration, with VFDs, 300L pressure tanks, and pressure transmitters. This ensures continuous water supply for production, avoiding shutdowns and spoilage. One pump runs while the other is on standby; if a failure occurs (e.g., motor fault, pipe blockage), the backup can switch in instantly via control system, ensuring seamless supply.

The one-VFD-controls-two-pumps design avoids needing separate VFDs per pump, reducing procurement cost. Also, only one VFD needs to be programmed in the PLC, simplifying wiring and logic, easing installation and debugging.

The security filter is a SUS304 40-inch, 4-core unit with 5μm PP cartridges to remove fine particles and protect downstream equipment. Valves and pressure gauges are included for monitoring.

(VII) UV Sterilization

Two 660W UV systems are used, each handling 30t/h.

While ozone offers ongoing disinfection, its concentration in tanks may drop over time (half-life: 20–30 minutes). Microbial regrowth from contamination may occur. UV sterilization is placed at the end of the outlet pipe after the tank, directly acting on water entering production. It instantly deactivates residual microbes (e.g., spores, viruses that ozone may miss), forming a “dual barrier” of ozone for storage and UV for final output. This ensures safe water for direct-contact applications like carcass washing and viscera processing, where full microbial inactivation is needed to prevent cross-contamination.

Figure 6: UV Sterilization System

(VIII) Automatic Control System

The PLC control cabinet receives device signals (level sensors, pressure transmitters, flow meters) and precisely controls parameters such as water temperature (e.g., 57–61°C for scalding, ≤4°C for chilling), pressure (e.g., ≥0.3MPa for washing), and disinfection concentration (e.g., ozone dosing based on flow). It ensures that water in all slaughterhouse processes consistently meets standards (e.g., ≥1.25L/bird/min overflow during chicken scalding, auto-adjusted via flow meter and valve). The intelligent system improves accuracy and reduces errors. Operators can monitor system status intuitively and intervene manually via interface, combining automation with flexibility.

Figure 7: PLC Control Cabinet

III. Conclusion

Throughout the production chain in slaughterhouses, water quality directly affects meat safety, production efficiency, and regulatory compliance. RO systems, as the core of deep purification, are critical across all stages and form an irreplaceable part of the process.

The equipment in this case was selected and designed by our engineering team. With our professional team and rich experience, choosing our water treatment system means your slaughterhouse stays free of water quality worries—every drop stands guard for your meat’s safety, bringing peace of mind to your profits!