1054 Activated Carbon Filter Tank

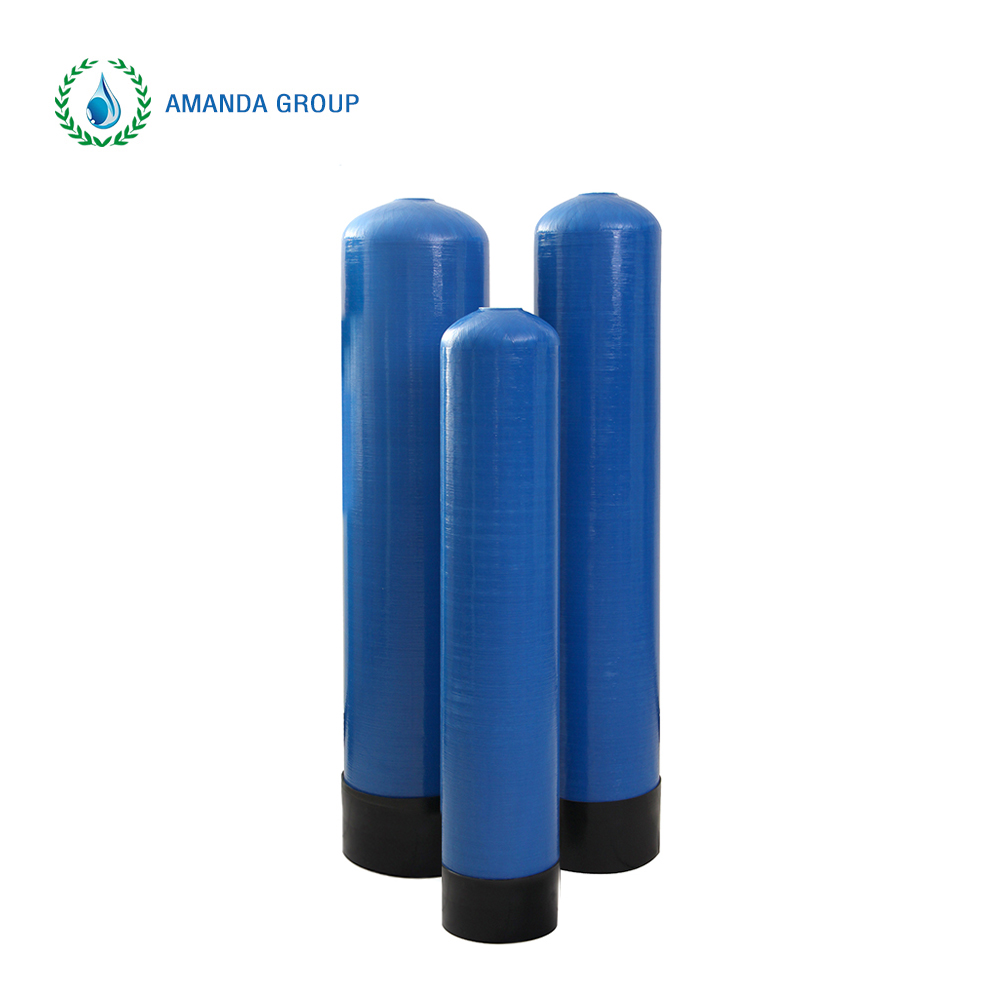

Introduction to 1054 FRP Storage Tanks

1054 FRP water tanks are used as carbon filters for pretreatment of RO water treatment plant systems to remove colour and odour from raw water. PE liner with FRP fibre wrap, widely used in residential or commercial softening and filtration systems. Completely rust-free and corrosion-free.

1054 FRP storage tank parameters and features:

Model: 1054

Shell material: FRP

Inner liner: PE

Max. operating pressure: 10.5 bar (150psi)

Top opening: 2.5″

Filtration: 0.6~1.5m3/hr

Operating temperature: 1~49℃

Colour options: natural/blue/black/grey/other custom colours

Applications of FRP water tanks:

1. Industrial water treatment of multi-layer media.

2. Water Softening.

3. Aquaculture, fish farming filtration systems

Suitable for use in hotels, food and beverage plants, farms, restaurants, retail, food shops, energy and mining, food and beverage industries.

Size and model selection

| Model | Vessel Size | Vol | Opening | Dimension/mm | Base |

| Inch | mm | L | Top | Bot. | LA | LB | LC | D |

| 2165/4T | 21x65 | 550x 1640 | 322 | 4"-8UN | / | 1640 | 1590 | / | 550 | FRP Round

|

| 2169/4T | 21x69 | 550x1750 | 322 | 4"-8UN | / | 1760 | 1590 | / | 550 | FRP Tripod |

| 2169/4T4B | 21x69 | 550x1750 | 322 | 4"-8UN | 4"-8UN | 1760 | 1575 | 185

| 550 | FRP Tripod |

| 2176/4T | 21x76 | 550x1910 | 326 | 4"-8UN | / | 1910 | 1600 | 320 | 550 | FRP Round |

| 2176/4T4B | 21x76 | 550x1910 | 326 | 4"-8UN | 4"-8UN | 1910 | 1590 | 320 | 550 | FRP Tripod |

| 2468/4T | 24x68 | 615x1735 | 427 | 4"-8UN | /

| 1735 | 1690 | / | 615 | FRP Tripod |

| 2472/4T | 24x72 | 615x 1850 | 427 | 4"-8UN | / | 1850 | 1690 | / | 615 | FRP Round |

| 2472/4T4B | 24x72 | 615x1850 | 427 | 4"-8UN | 4"-8UN | 1850 | 1680 | 170 | 615 | FRP Tripod

|

| 2485/4T | 24x85 | 615x2150 | 471 | 4"-8UN | / | 2150 | 1830 | /

| 615 | FRP Tripod

|

| 2485/4T4B | 24x85 | 918x2150 | 471 | 4"-8UN | 4"-8UN | 2150 | 1830 | 320 | 615 | FRP Tripod |

| 3068/4T | 30x68 | 780x1730 | 690 | 4"-8UN | / | 1730 | 1690 | / | 780 | FRP Tripod |

3072/4T | 30x72 | 780x1850 | 690 | 4"-8UN | / | 1850 | 1690 | / | 780 | FRP Tripod |

3072/4T4B | 30x72

| 780x1850 | 690 | 4"-8UN | 4"-8UN | 1850 | 1680 | 175 | 780 | FRP Tripod |

| 3085/4T | 30x85 | 780x2150 | 758 | 4"-8UN | / | 2150 | 1830 | / | 780 | FRP Tripod |

| 3085/4T4B | 30x85 | 780x 2150 | 758 | 4"-8UN | 4"-8UN | 2150 | 1830 | 320 | 780 | FRP Tripod |

| 3087/6T6B | 30x87 | 780x 2200 | 728 | 6"-flane | 6"-flange | 2200 | 1935 | 265 | 780 | FRP Tripod |

| 3672/4T4B | 36x72 | 918x 1850 | 850 | 4"-8UN | 4"-8UN | 1850 | 1610 | 240 | 918 | FRP Tripod |

| 3685/4T4B | 36x85 | 918x 2150 | 1023 | 4"-8UN | 4"-8UN | 2150 | 1830 | 320 | 918 | FRP Tripod |

| 3689/6T6B | 36x89 | 918x 2260 | 1023 | 6"-flane | 6"-flange | 2260 | 1940 | 320 | 918 | FRP Tripod |

| 3694/6T6B | 36x94 | 918x 2400 | 1205 | 6"-flane | 6"-flange | 2400 | 2140 | 260 | 918 | FRP Tripod |

| 4072/4T4B | 40x72 | 1020x 1850 | 1046 | 6"-flane | 6"-flange | 1850 | 1605 | 245 | 1020 | FRP Tripod |

| 4094/6T6B | 40x94 | 1020x 2400 | 1332 | 6"-flane | 6"-flange | 2400 | 2155 | 225 | 1020 | FRP Tripod |

| 4272/6T6B | 42x72 | 1088x 1850 | 1100 | 6"-flane | 6"-flange | 1850 | 1615 | 235 | 1088 | FRP Tripod |

| 4289/6T6B | 42x89 | 1088x 2270 | 1389 | 6"-flane | 6"-flange | 2270 | 1950 | 320 | 1088 | FRP Tripod |

| 4872/6T6B | 48x72 | 1218x 1850 | 1308 | 6"-flane | 6"-flange | 1850 | 1565 | 285 | 1218 | FRP Tripod |

| 4889/6T6B | 48x89 | 1218x 2270 | 1743 | 6"-flane | 6"-flange | 2270 | 1950 | 320 | 1218 | FRP Tripod |

| 4894/6T6B | 48x94 | 1218x 2400 | 1909 | 6"-flane | 6"-flange | 2400 | 2110 | 290 | 1218 | FRP Tripod |

| 48110/6T6B | 48x110 | 1218x 2800 | 2360 | 6"-flane | 6"-flange | 2800 | 2510 | 290 | 1218 | FRP Tripod |

| 6094/6T6B | 60x94 | 1530x 2400 | 2688 | 6"-flane | 6"-flange | 2400 | 2110 | 290 | 1530 | FRP Tripod |

| 60110/6T6B | 60x110 | 1530x 2800 | 3392 | 6"-flane | 6"-flange | 2800 | 2510 | 290 | 1530 | FRP Tripod |

| 6383/6T6B | 63x83 | 1620x 2100 | 2580 | 6"-flane | 6"-flange | 2100 | 1780 | 320 | 1620 | FRP Tripod |

| 6394/6T6B | 63x94 | 1620x 2400 | 3150 | 6"-flane | 6"-flange | 2400 | 2080 | 320 | 1620 | FRP Tripod |

| 7294/6T6B | 72x94 | 1836x 2400 | 3561 | 6"-flane | 6"-flange | 2400 | 2045 | 355 | 1836 | FRP Tripod |

*The actual dimmension may have ±1.2% error due to PE materlats contraction coefficient

PRODUCT DISPLAY

Product advantage:

FRP tank is made up of resin and glass fiber by microcomputer control winding machine and become a kind of non-metallic

comoosite tanks. it has corrosion resistance. hiah strenath. lona service life. can be flexible desian. workmanshiD, etc

PRODUCING PROCESS

Amanda fiber reinforced polymer tanks processes used for manufacturing :

1. 6” to 36" PE liners are made from CNC controlled blow molding machine ,

2. PE liner of industrial tanks are made from CNC controlled rotational molding machine ,

3. Inlet inserts and bases are from CNC controlled injection molding machine,

4. FRP outer shells are made from CNC controlled multi-axis filament winding machine.

PRODUCTION PROCESS

PACKAGE AND SHIPPING

1. Client's Requirements are in the first :

We are gald to customized package as per clients's demands, including logo and colors design , importantly the fiber reinforced polymer tanks also can do client's brand insteading of our manufacturer's .

2. Normally Amanda Company package is by waterproof plastic bag with carton box.

Kindly supply pictures for your reference .

Exhibition

Our Advantage

Our Factory

Advanced production equipment |

|

Professional and technical personnel

|

Adequate product inventory |

|

Rich industry experience |