Commercial application

UV Irradiation Pretreatment

Before the water passes through the UV unit, it should be filtered with sediment or activated carbon. Particulate matter, color and turbidity can interfere with the transmission of UV light to microorganisms and therefore must be removed for successful disinfection.

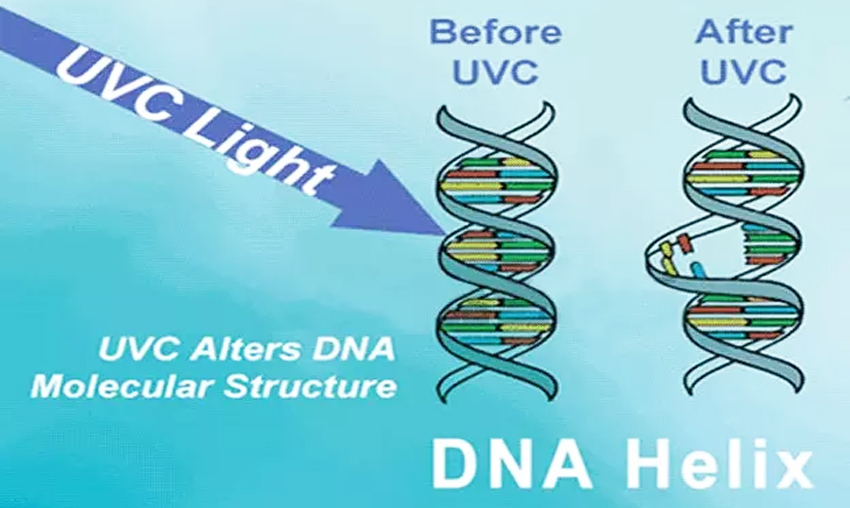

Sterilization Principe

Blasting the flowing water with high-intensity germicidal UVC eliminates more than 60 waterborne pathogens, including algae, bacteria, cysts and viruses. The UVC disinfection lamp is housed in an industrial graphite housing optimized for high flow rates. A highly specialized quartz glass casing protects the lamp from water penetration while transmitting 99.9% UV light. The highly concentrated electromagnetic energy destroys organic matter and eliminates the formation of dangerous chlorine byproducts called chloramines, which often cause red eyes, stinging, skin irritation, asthma and allergies. This energy penetrates the cell walls of bacteria, viruses, algae, cysts and all pathogens.

Operating Conditions

Environmental conditions:

1. Temperature: 5"C -40C

2. Relative humidity: s90% (at ambient temperature 25*C

3. Power supply: 10V/220V/240W/380V , 50Hz/60Hz

4. Max. operating pressure: s 1.0MPa

Water supply requirements:

| Parameter | Standard |

| Fe | ≤0.3 (mg/) |

| Hydrogen sulfide | ≤0.05 (mg/) |

| Suspended solid | ≤10 (mg/) |

| Mn | ≤0.05 (mg/) |

| Hardness | ≤120 (mg/) |

| Chroma | ≤15 (degree) |

| Turbidity | ≤5 (NTU) |

| Water temperature | 5°C ~60C |

Parameter

| Model | Flow Rate @ 30mj/cm² | Lamp Watts | Lamp Qty | Inlet/outlet Port | Reactor Size(mm) |

| GPM | TPH | L | W | H |

| AMD-CUV-80 | 24 | 5.5 | 40 | 2 | G1 1/4" M Thread | 920 | 100 | 233 |

| AMD-CUV-120 | 35 | 8 | 40 | 3 | G1 1/2" M Thread | 920 | 159 | 300 |

| AMD-CUV-160 | 44 | 10 | 40 | 4 | G1 1/2" M Thread | 920 | 159 | 300 |

| AMD-CUV-160 | 53 | 12 | 80 | 2 | DN50 | 920 | 101 | 300 |

| AMD-CUV-240 | 88 | 20 | 80 | 3 | DN65 | 920 | 133 | 320 |

| AMD-CUV-320 | 110 | 25 | 80 | 4 | DN80 | 975 | 159 | 380 |

| AMD-CUV-360 | 132 | 30 | 120 | 3 | DN80 | 1350 | 159 | 380 |

| AMD-CUV-480 | 154 | 35 | 80 | 6 | DN100 | 920 | 219 | 400 |

| AMD-CUV-600 | 176 | 40 | 120 | 5 | DN100 | 1250 | 159 | 580 |

| AMD-CUV-620 | 198 | 45 | 155 | 4 | DN100 | 1660 | 159 | 380

|

| AMD-CUV-720 | 220 | 50 | 120 | 6 | DN100 | 1250 | 168 | 530

|

| AMD-CUV-775 | 242 | 55 | 155 | 5 | DN100 | 1660 | 219 | 550

|

| AMD-CUV-930 | 286 | 65 | 155 | 6 | DN125 | 1660 | 219 | 530

|

| AMD-CUV-1085 | 330 | 75 | 155 | 7 | DN125 | 1660 | 219 | 480

|

| AMD-CUV-1240 | 420 | 95 | 155 | 8 | DN125 | 1600 | 219 | 480

|

| AMD-CUV-1600 | 490 | 110 | 320 | 5 | DN150 | 1600 | 280 | 550

|

| AMD-CUV-1920 | 660 | 150 | 320 | 6 | DN200 | 1600 | 300 | 550

|

* The above pictures and parameters are only for reference. We conserve all rights of parameter modification without prior notiiccation.

Product Advantages

*Immediate and safe disinfection without added chemicals.

*The odor and taste of the water is not affected.

*Simple installation without any reaction vessels or tanks.

*Economical maintenance costs.

Product Application

Pure Water: Drinking water; Tap water factory; Food process water; Hospital and Pharmaceutical; Beer industry; Hotel; Lab ultrapure water; Cosmetics industry.

Circulating Water: Water entertainment facilities swimming pool water; Landscape water; Industrial circulating cool water;Spa; Micro-electronics.

Wastewater: Municipal sewage; Hospital sewage; Oilfield reinjection water; Urban sewage; Reclaimed water;Slaughter-house wastewater; Sewage from ships.

Aquaculture: Hydroponic shellfish; Fish hatcheries; Farms;Aquarium.Military bases, Field operations, Aircraft, Ships, Submarine water disinfection.

Swimming Pool Water Swimming Pool Water |

|  Campus Water Seilization Campus Water Seilization |

|  Non-Soil Cltvation Non-Soil Cltvation |

UV Light Purification Advantages

1. High efficient UV Light Purification:

Normally kill 99-99.99% bacteria within 1 to 2 seconds.

2. Broad spectrum:

UV Light Purification has broadest spectrum, can kill almost all bacteria and virus.

3. No secondary pollution:

Do not add any chemical, so can not create secondary pollution to water and ambient environment, and do not change any ingredient in water.

4. Safe and reliable to operate:

Traditional disinfection technologies, such as chloride or ozone, which disinfection agent itself are highly toxic and flammable material while 48 gpm uv light sterilizer has no such potential safety hazard.

5. Low maintenance fee:

UV lamps occupies a small area; structure requirement is simple, so total investment is smaller. Lower in operation, it costs only half than that chlorine disinfection in kiloton water treatment.

UV Light Purification Advantage Than Others Way

Methods | UV | Chlorination | Ozone |

| Destruction | Physical | Chemical | Chemical |

| Capital Cost | Low | Medium | High |

| Operating Cost | Low | Medium | High |

| Maintenance Cost | Low | Medium | High |

| Maintenance Frequency | Low | Medium | High |

| Disinfection Performance | Excellent | Very good | Unpredictable |

Contact time | 1-5 Seconds | 25-24 minutes | 5-10 Minutes |

| Persanal Hazards | Low | Medium | High |

| Toxic Chemicals | No | Yes | Yes |

| Water Chemistry Change | No | Yes | Yes |

| Residual Effect | No | Yes | Yes |

Working Theory Of UV Light Purification

UV Light Purification is invisible, exists in the outside of UV spectrum,so it is called UV radiaction. According to a different wavelength range,they are cut into A, B, C three kinds of bands, including the C-band UV wavelength between 240-260nm, which is the most effective sterilizer band, band's strongest point it the wavelength of 253.7nm.

Swimming pool disinfection system

Where Need UV Light Purification?

Pure Water: Drinking Water;Tap Water Factory; Food Process Water; Hospital and Pharmaceutical;

Beer Industry; Hotels; Lab Ultrapure Water;Cosmetics Industry.

Circulating Water: Water Entertainment Facilities&Swimming pool water; Landscape water; Industrial Circulating Cooling Water; Spa; Micro-electronics.

Wastewater: Municipal Sewage; Hospital Sewage; Oilfield Reinjection Water; Urban Sewage;Reclaimed Water; Slaughter-house Wastewater; Sewage from Ships.

Aquaculture: Hydroponic Shellfish; Fish Hatcheries; Farms; Aquarium.

Exhibition

Our Advantage

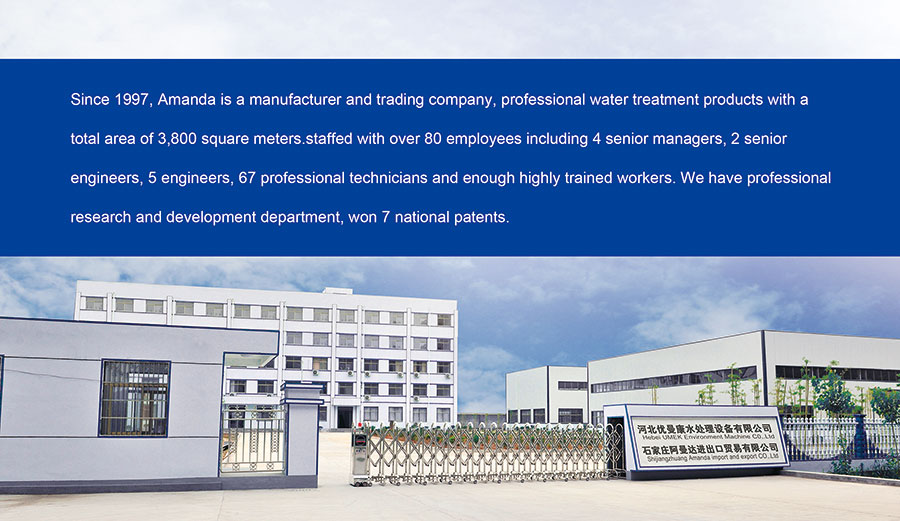

Our Factory

Advanced production equipment Advanced production equipment |

|  Professional and technical personnel Professional and technical personnel |

Adequate product inventory |

|

Rich industry exporience |

Professional and technical personnel

Professional and technical personnel