High Flow String Wound Sediment Filter Description

High Flow String Wound Sediment Filter Material

The raw material is 100% pure polypropylene, the yarn is washed by warm water, no silicon, no fluorescence. The latest winding technology is used to ensure it's real depth filtering efficiency.

Length: 10"-40", micron: 0.5 u m-300μm, filtration precision 0.5-300μm, all kinds of precision are tested in Japan, can guarantee customer's different requirement. JPW water filter has passed the certification of the NSF/ANSl 42, is approved by the NSF as drinking water security filter. Our filter polypropylene yarn and polypropylene core, which is used to make string wound filter cartridge,is all produced by ourselves, strictly controlled in the very beginning,ensure the superior product quality.

High Flow String Wound Sediment Filter

High Flow string wound filter is patented in China by SF Filter. Using multi-holes to make the filter 9 times dirt holding capacity as ordinary string wound cartridges. With O-rings to avoid bypass. 3 grades are available,HF A,HFB and HFC can meet most pre-filtration requirements.

Pure,clean and washed material which is same as NSF APPROVED TYPE(HFA).

Pure material,suitable for strong corrosion liquids (HFB).

common material,allows lower price (HFC).

Special string wound filter for power plant

Application:power plant condensed water filtration

RO (reverse osmosis) security filtering,sea water desalination processing,industrial water, electric plating solution filter, Chemical industry, electronics industry solution filter

Cotton Wound Filter

The cotton thread is made of natural cotton after decreasing In accordance with the specific density of precision winding on the porous stainless steel core.

Feature:stand for high temperature 120 degree. Big flow, good filtration performance.

Apply to food,edible oil,hot water filtration.

Our Advantage

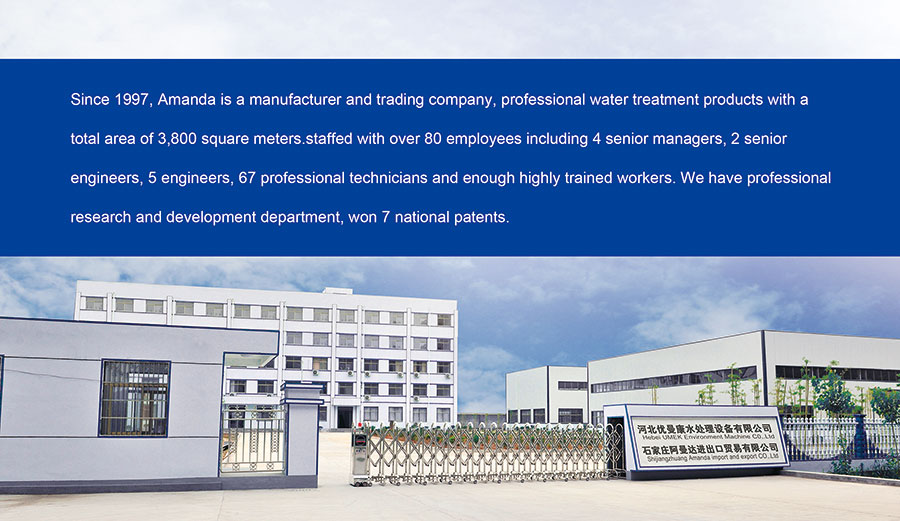

Our Factory

Advanced production equipment |

|

Professional and technical personnel |

Adequate product inventory |

|

Rich industry experience |