Oilfield Re-injection Water UV Sterilizer

Background to the use of oilfield re-injection water disinfectors

Oilfield reinjection water UV disinfector sterilisation combined with regular impact injection of chemical biocides has become the most economical means of avoiding microbial contamination in oilfield injection water, killing both aerobic and anaerobic bacteria. Oilfield water disinfection also greatly reduces the frequency of chemical use, therefore reducing the cost of managing and transporting chemicals.

A range of processes are often required to meet the requirements of oilfield injection water quality, and combining oilfield re-injection water disinfection with other water treatment processes is a proven means of doing so. Oilfield re-injection UV disinfection systems can be used as the final link in the water treatment process; avoiding the secondary biological contamination of water caused by other processes.

Sterilization Principe

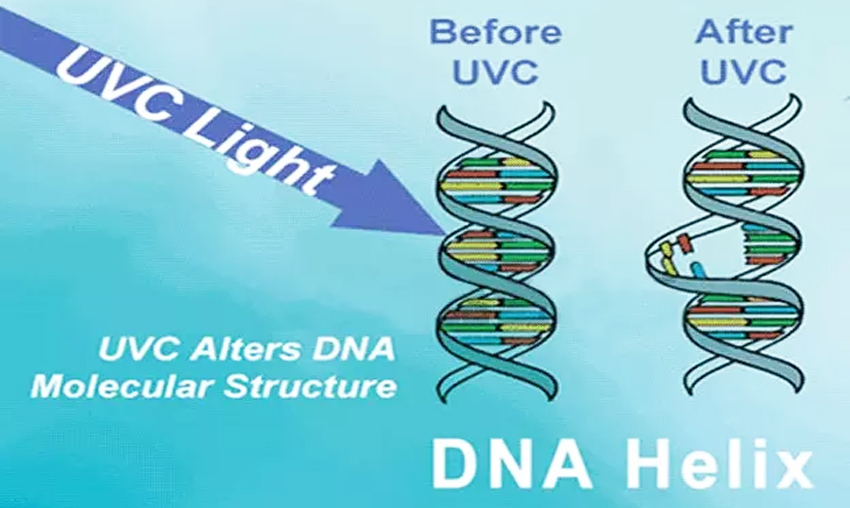

UV ray is an invisible light, locating at outer side of violet rays in the spectrogram, Therefore it is clled as ultraviolet light, with wave length between 100nm and 400nm, UV ray can be divided intoA, B, C and vacuum ultra violets as per the wave length, Ultraviolet C is shortened to UV-C with wave length between 200nm and 280nm, UV-C with wave length of 253.7nm has the best sterilization effect, which is origin of modern UV-C.

Operating Conditions

Environmental conditions:

1. Temperature: 5"C -40C

2. Relative humidity: s90% (at ambient temperature 25*C

3. Power supply: 10V/220V/240W/380V , 50Hz/60Hz

4. Max. operating pressure: s 1.0MPa

Water supply requirements:

| Parameter | Standard |

| Fe | ≤0.3 (mg/) |

| Hydrogen sulfide | ≤0.05 (mg/) |

| Suspended solid | ≤10 (mg/) |

| Mn | ≤0.05 (mg/) |

| Hardness | ≤120 (mg/) |

| Chroma | ≤15 (degree) |

| Turbidity | ≤5 (NTU) |

| Water temperature | 5°C ~60C |

Parameter

| Model | Flow Rate | Power |

| M3/H | GPM |

| AMD-M50LT | 50 | 220 | 1.3 |

| AMD-M100LT | 100 | 440 | 2.0 |

| AMD-M150LT | 150 | 660 | 3.0 |

| AMD-M200LT | 200 | 880 | 4.0 |

| AMD-M300LT | 300 | 1320 | 6.0 |

| AMD-M400LT | 400 | 1760 | 8.0 |

| AMD-M450LT | 450 | 1980 | 9.0 |

| AMD-M500LT | 500 | 2200 | 10 |

| AMD-M600LT | 600 | 2640 | 12 |

| AMD-M650LT | 650 | 2860 | 13 |

| AMD-M700LT | 700 | 3080 | 14 |

| AMD-M750LT | 750 | 3300 | 15 |

| AMD-M800LT | 800 | 3500 | 16 |

| AMD-M900LT | 900 | 3960 | 18 |

| AMD-M1000LT | 1000 | 4400 | 20 |

* The above pictures and parameters are only for reference. We conserve all rights of parameter modification without prior notiiccation.

Product Advantages

The oilfield re-injection UV disinfector is compact, modular and easy to install in existing pipelines, making it very convenient and simple to install. The impact dosing of chemicals does not require sophisticated monitoring equipment, but if chemical disinfectants alone are used as the primary means of disinfection, they must be controlled with accurate monitoring equipment.

Bacteria control has become an important topic for the oil and gas industry. Improper sterilisation treatments can have important consequences, these include hydrogen sulphide gas acidifying the reservoir, microorganisms causing corrosion or liquids losing stability during stimulation.

Product Application

Municipal water, Swimming pool, Seedling breeding, Pharmaceutical industry, Fruit juice beverage industry, etc.

UV Light Purification Advantages

1. High efficient UV Light Purification:

Normally kill 99-99.99% bacteria within 1 to 2 seconds.

2. Broad spectrum:

UV Light Purification has broadest spectrum, can kill almost all bacteria and virus.

3. No secondary pollution:

Do not add any chemical, so can not create secondary pollution to water and ambient environment, and do not change any ingredient in water.

4. Safe and reliable to operate:

Traditional disinfection technologies, such as chloride or ozone, which disinfection agent itself are highly toxic and flammable material while 48 gpm uv light sterilizer has no such potential safety hazard.

5. Low maintenance fee:

UV lamps occupies a small area; structure requirement is simple, so total investment is smaller. Lower in operation, it costs only half than that chlorine disinfection in kiloton water treatment.

UV Light Purification Advantage Than Others Way

Methods | UV | Chlorination | Ozone |

| Destruction | Physical | Chemical | Chemical |

| Capital Cost | Low | Medium | High |

| Operating Cost | Low | Medium | High |

| Maintenance Cost | Low | Medium | High |

| Maintenance Frequency | Low | Medium | High |

| Disinfection Performance | Excellent | Very good | Unpredictable |

Contact time | 1-5 Seconds | 25-24 minutes | 5-10 Minutes |

| Persanal Hazards | Low | Medium | High |

| Toxic Chemicals | No | Yes | Yes |

| Water Chemistry Change | No | Yes | Yes |

| Residual Effect | No | Yes | Yes |

Working Theory Of UV Light Purification

UV Light Purification is invisible, exists in the outside of UV spectrum,so it is called UV radiaction. According to a different wavelength range,they are cut into A, B, C three kinds of bands, including the C-band UV wavelength between 240-260nm, which is the most effective sterilizer band, band's strongest point it the wavelength of 253.7nm.

Swimming pool disinfection system

Where Need UV Light Purification?

Pure Water: Drinking Water;Tap Water Factory; Food Process Water; Hospital and Pharmaceutical;

Beer Industry; Hotels; Lab Ultrapure Water;Cosmetics Industry.

Circulating Water: Water Entertainment Facilities&Swimming pool water; Landscape water; Industrial Circulating Cooling Water; Spa; Micro-electronics.

Wastewater: Municipal Sewage; Hospital Sewage; Oilfield Reinjection Water; Urban Sewage;Reclaimed Water; Slaughter-house Wastewater; Sewage from Ships.

Aquaculture: Hydroponic Shellfish; Fish Hatcheries; Farms; Aquarium.

Exhibition

Our Advantage

Our Factory

Advanced production equipment Advanced production equipment |

|  Professional and technical personnel Professional and technical personnel |

Adequate product inventory |

|

Rich industry exporience |

Professional and technical personnel

Professional and technical personnel