FRP WaTER PRESSURE TANK

MAIN TECHNICAL FEATURE

Characters

Fully Rustproof and corrosion resistant

High strength Light weight

Easy transporting and istllation

Nice appearance

Structure & Materials

Liner material: Rotation molding or Blowing One-piece seamless PE inner liner

Outer Winding: Hight Performance resin with Fiber glass threedimensional winding

Opening: 2.5" and 4" reinforced plastic thread,6" alloy flange

Bass Materials: FRP or reinforced PP

Application Conditions

Working Pressure:150psi (10.5bar)

Working Temperature:1-49*C (34-121*F)

Max.Vacuum:127mm Hg

Lowest Environment Temperature: -27*C (-17*F)

Design Parameter

Burst Pressure: 42bar (4 times)

Fatigue Cycle: 100, 000

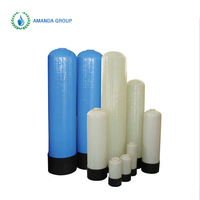

Color

In UMK fiber reinforced polymer tanks, there are five colors for your choose : Nature,

Blue, Black, Gray, Yellow. ( Other colors are customied )

Specification

AMANDA-S TANK SPECIFICATION

| Model | Vessel Size | Vol | Opening | Dimension/mm | Base |

| Inch | mm | L | Top | Bot. | LA | LB | LC | D |

0713/2.5T | 7x13 | 181x335 | 6.3 | 2.5"NPSM | / | 335 | 330 | / | 181 | PP

|

| 0717/2.5T | 7x17 | 181x440 | 8.5 | 2.5"NPSM | / | 440 | 435 | / | 181 | PP |

| 0735/2.5T | 7x35 | 181x895 | 19.1 | 2.5"NPSM | / | 895 | 890 | / | 181 | PP |

| 0744-2.5T | 7x44 | 181x1125 | 24.3 | 2.5"NPSM | / | 1125 | 1120 | / | 181 | PP |

| 0813/5T | 8x13 | 205x335 | 7.4 | 2.5"NPSM | / | 335 | 330 | / | 205 | PP |

| 0817/2.5T | 8x17 | 205x440 | 10.5 | 2.5"NPSM | / | 440 | 433 | / | 205 | PP |

| 0835/2.5T | 8x35 | 205x 895 | 23.6 | 2.5"NPSM | / | 895 | 888 | / | 205 | PP |

| 0844/2.5T | 8x44 | 205x1125 | 31.3 | 2.5"NPSM | / | 1125 | 1118 | / | 205 | PP |

| 0917/2.5T | 9x17 | 232x440 | 13.2 | 2.5"NPSM | / | 440 | 890 | / | 232 | PP |

| 0935/2.5 | 9x35 | 232x898 | 31.6 | 2.5"NPSM | / | 898 | 1067 | / | 232 | PP |

| 0942/2.5T | 9x42 | 232x1074 | 38.5 | 2.5"NPSM | / | 1074 | 1221 | / | 232 | PP |

0948/2.5 | 9x48 | 232x1228 | 44.6 | 2.5"NPSM | / | 1228 | 430 | / | 232 | PP |

1017/2.5T | 10x17 | 257x450 | 16.5 | 2.5"NPSM | / | 450 | 890 | / | 257 | PP |

| 1035/2.5T | 10x35 | 257x910 | 38.3 | 2.5"NPSM | / | 910 | 1114 | / | 257 | PP |

| 1044/2.5T | 10x44 | 257x1130 | 49.5 | 2.5"NPSM | / | 1130 | 1370 | / | 257 | PP |

| 1054/2.5T | 10x54 | 257x1388 | 61.9 | 2.5"NPSM | / | 1388 | 1214 | / | 257 | PP |

| 1248/2.5T | 12x48 | 307x1220 | 77.3 | 2.5"NPSM | / | 1220 | 1328 | / | 307 | PP |

| 1252/2.5T | 12x52 | 307x1335 | 84.8 | 2.5"NPSM | / | 1335 | 1640 | / | 307 | PP |

| 1265/2.5T | 12x65 | 307x1650 | 106.3 | 2.5"NPSM | / | 1650 | 1127 | / | 307 | PP |

| 1344/2.5T | 13x44 | 334x1135 | 82.9 | 2.5"NPSM | / | 1135 | 1392 | / | 334 | PP |

| 1354/2.5T | 13x54 | 334x1400 | 103.6 | 2.5"NPSM | / | 1400 | 1780 | / | 334 | PP |

| 1465/2.5T | 14x65 | 360x1662 | 145.6 | 2.5"NPSM | / | 1662 | 1654 | / | 360 | PP |

| 1465/4T | 14x65 | 360x1662 | 145.6 | 4"-8UN | / | 1662 | 1654 | / | 360 | PP |

| 1665/2.5T | 16x65 | 410x1670 | 187.7 | 2.5"NPSM | / | 1670 | 1662 | / | 410 | PP |

| 1665/4T | 16x65 | 410x 1670 | 187.7 | 4"-8UN | / | 1670 | 1662 | / | 410 | PP |

| 1665/4T4B | 16x65 | 410x 1830 | 187.7 | 4"-8UN | 4"-8UN | 1830 | 1650 | 180 | 410 | FRP Tripod |

| 1865/4T | 18x65 | 465x 1675 | 249 | 4"-8UN | / | 1670 | 1660 | / | 465 | FRP Round |

| 1865/4T4B | 18x65 | 465x 1825 | 249 | 4"-8UN | 4"-8UN | 1830 | 1650 | 180 | 465 | FRP Tripod |

*The actual dimmension may have ±1.2% error due to PE materlats contraction coefficient

PRODUCT DISPLAY

Product advantage:

FRP tank is made up of resin and glass fiber by microcomputer control winding machine and become a kind of non-metallic

comoosite tanks. it has corrosion resistance. hiah strenath. lona service life. can be flexible desian. workmanshiD, etc

PRODUCING PROCESS

Amanda fiber reinforced polymer tanks processes used for manufacturing :

1. 6” to 36" PE liners are made from CNC controlled blow molding machine ,

2. PE liner of industrial tanks are made from CNC controlled rotational molding machine ,

3. Inlet inserts and bases are from CNC controlled injection molding machine,

4. FRP outer shells are made from CNC controlled multi-axis filament winding machine.

PRODUCTION PROCESS

PACKAGE AND SHIPPING

1. Client's Requirements are in the first :

We are gald to customized package as per clients's demands, including logo and colors design , importantly the fiber reinforced polymer tanks also can do client's brand insteading of our manufacturer's .

2. Normally Amanda Company package is by waterproof plastic bag with carton box.

Kindly supply pictures for your reference .

Exhibition

Our Advantage

Our Factory

Advanced production equipment |

|

Professional and technical personnel

|

Adequate product inventory |

|

Rich industry experience |