Ion Exchange Resin For EDM Machine Description

The liquid medium plays a role in cooling and chip removal in EDM. The medium used in WEDM is emulsion. The EDM piercer uses tap water or purified water. The slow wire cutting uses deionized pure water, and the medium used by EDM is spark kerosene. Deionized water softened water is not completely insulated, and it can be broken down and conductive at a certain voltage.

It is completely insulated at low voltage. Under the design voltage, the liquid is broken down, and the discharge and whose blast shock wave act on the processing surface simultaneously, and the processing chips are taken away.

Softened water is also called deionized water. It is to remove calcium and magnesium ions from water to reduce the hardness of water, make the surface of machine tool cleaner and work better.

We can provide EDM machine ion water equipment, but also accessories: moistening valve, frp tank, ion exchange resin, softened water equipment accessories often bought by customers include ion exchange resin and FRP tank.

Introduction to FRP tank:

Product Description:

FRP pressure vessel, also known as FRP tank, is made of reinforced glass fiber, high-performance epoxy resin as binder, PE liner as model and three-dimensional winding with automatic control equipment.

Product function:

In the water treatment system, it is used to fill the filter medium for the incoming water to contact with the filter medium and to act as a water container;

When working, you need to have a certain pressure bearing capacity;

According to the customer's requirements of water flow and exchange capacity to choose models.

characteristic:

(1) Food grade PE liner

(2) Corrosion resistance.

(3) Strength designability.

(4) High fatigue resistance.

(5) Overload safety.

(6) Good shock absorption.

(7) Good thermal stability.

EDM machine Common FRP tank models are 844/948/1054/1252

Introduction of ion exchange resin:

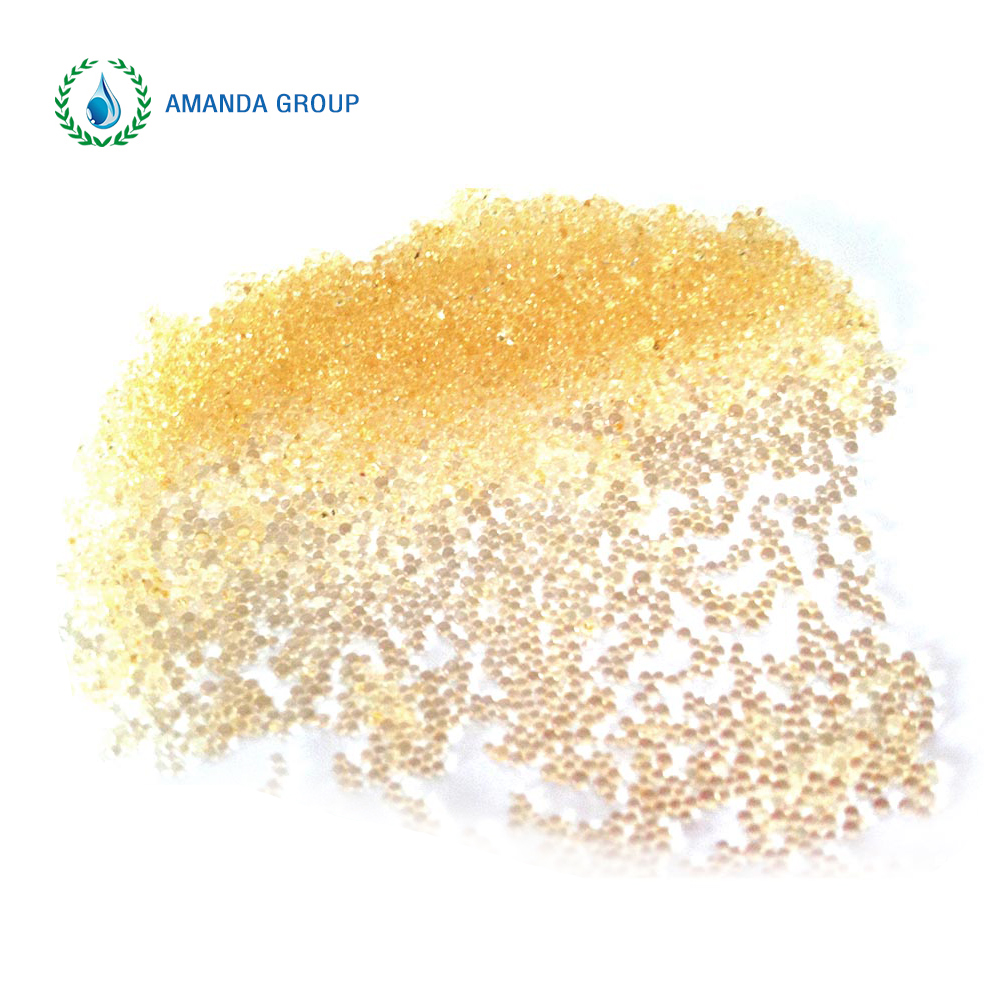

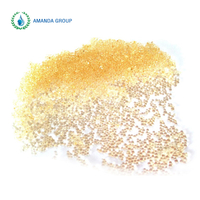

Appearance:

spherical gel grains

Color: amber to brown

Polymer structure: polystyrene gel crosslinked with divinylbenzene

Bulk density: 720-750 g / l

Ionic form as delivered: H + / OH-

Volume ratio of cation / anion exchanger: 46-55% / 54-45%

Maximum uniformity coefficient, no more: 1.7

Full static exchange capacity for Na +, not less: 2.0 mmol / cm3

Full static exchange capacity for Cl-, not less: 1.3 mmol / cm3

Maximum humidity (as delivered): 62%

Maximum working temperature: 60 ℃

PH working range: 0-14

Structure:

polystyrene sulfonic acid 20-30%

polyvinylbenzyl-trimethylammonium hydroxide 20-30%

water - 40-65%

Deionized water softened water is used for low EDM machine:

The low speed EDM machine and electrical pole wire takes copper wire as tool electrode, generally makes unidirectional movement at a speed lower than 0.2m/s, applies 60-300v pulse voltage between copper wire and processed materials such as copper wire, steel or super hard alloy, and maintains a gap of 5-50um. The gap is filled with insulating medium such as deionized water (softened water), so that spark discharge occurs between the electrode and the processed object, And each other is consumed and corroded, and countless small pits are etched on the surface of the workpiece. Through the monitoring and control of CNC control and the servo mechanism, the discharge phenomenon is uniform and consistent, so that the processed objects are processed, and the products with the required size and shape accuracy can be achieved. At present, the precision can reach 0.001mm, and the surface quality is close to the grinding level. The electrode wire is no longer used after discharge, and the non resistance and electrolysis power supply is adopted. Generally, it is equipped with automatic threading and constant tension device. The work is stable, even, jitter is small, the machining precision is high and the surface quality is good, but it is not suitable to process large thickness workpiece. Because of the precision of machine structure, high technology content and high machine price, the cost of using is also high.

| Product Name | Ion Exchange Resin for Low Speed EDM Machine Softening Water Deionized Water |

| Particle Size Range(%)

| 0.315-1.25mm≥90 |

| Coefficient of Uniformity

| <1.7 |

| Effective Grain Size(mm)

| 0.4-0.6mm |

| True Density(g/ml)

| 1.25-1.30 |

| Bulk Density(g/ml)

| 0.75-0.85 |

| Total Exchange Capacity(mmol/ml)

| ≥1.9 |

| Quality Total Exchange Capacity(mmol/g)

| ≥4.5 |

Ion Exchange Resin Application

Ion Exchange Resin Application

Exhibition

Our Advantage

Our Factory

Advanced production equipment |

|

Professional and technical personnel

|

Adequate product inventory |

|

Rich industry experience |